Leap

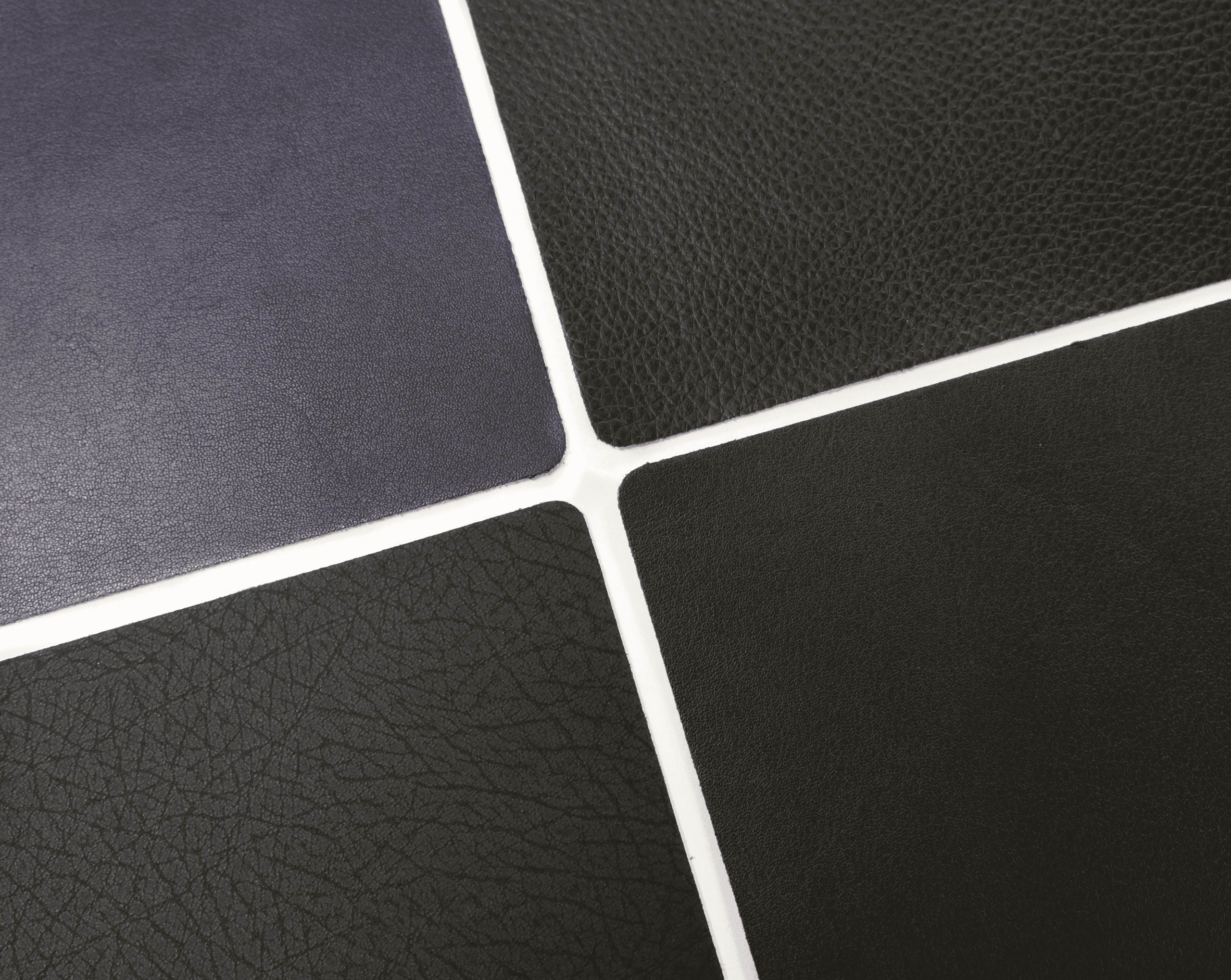

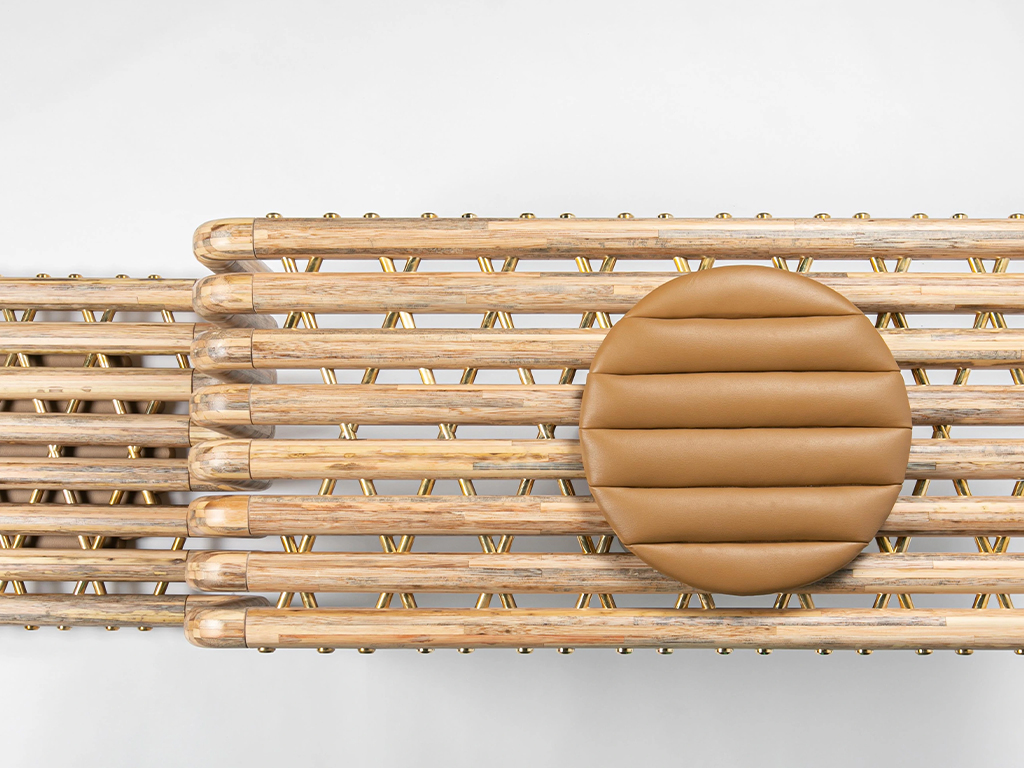

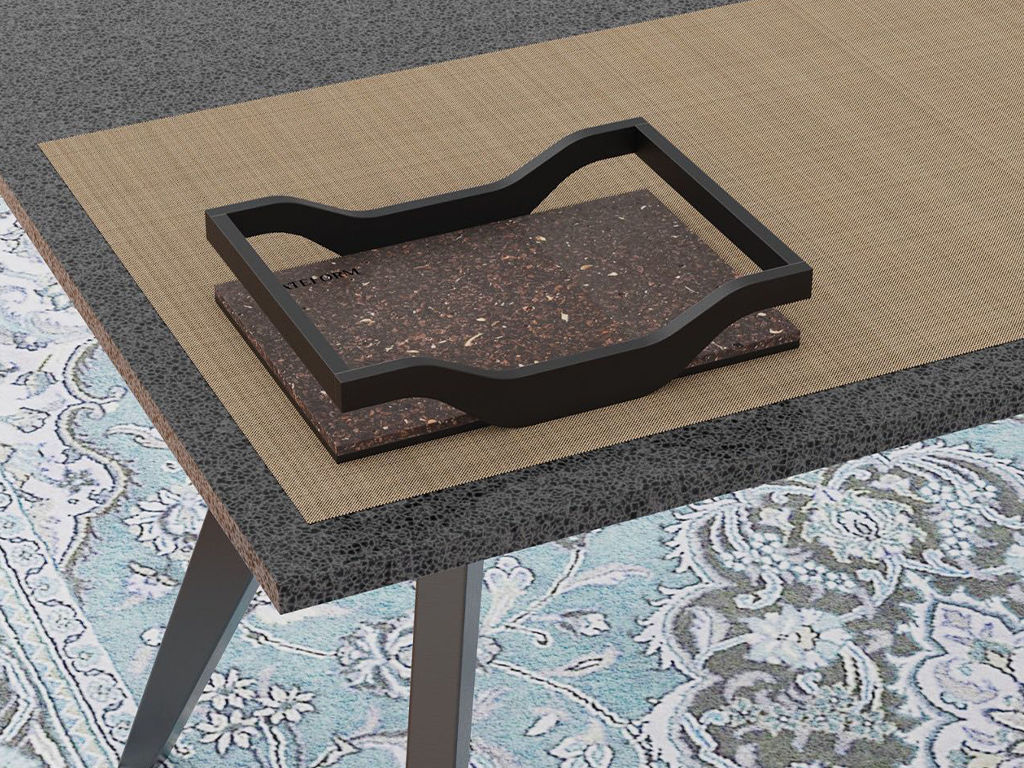

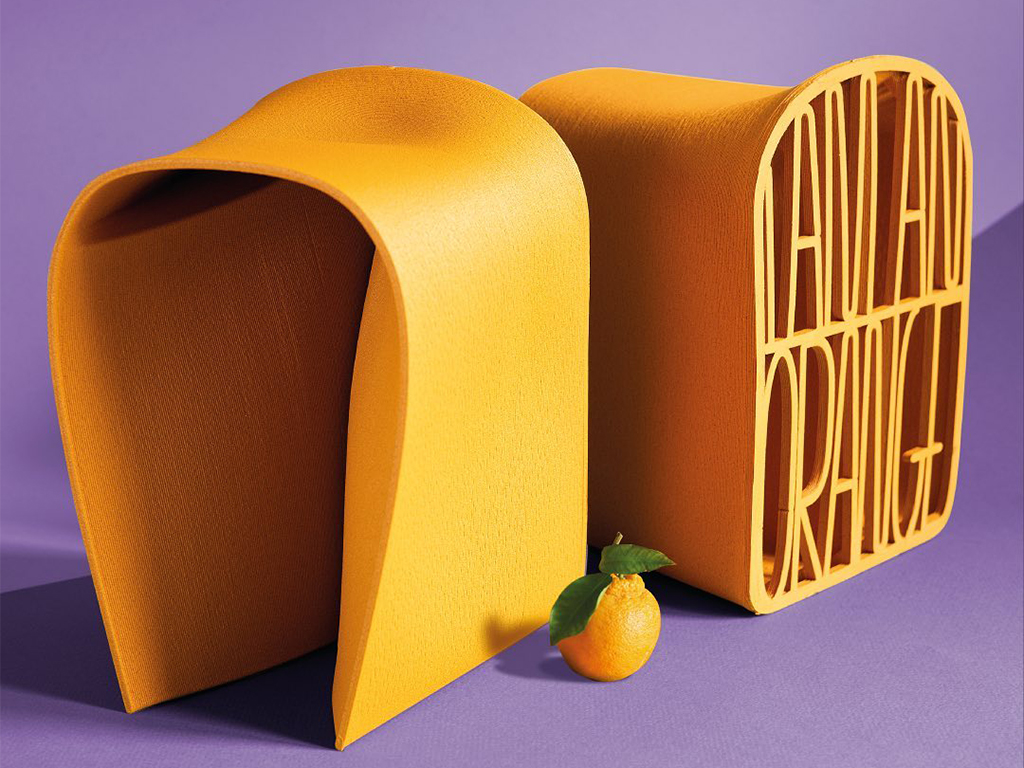

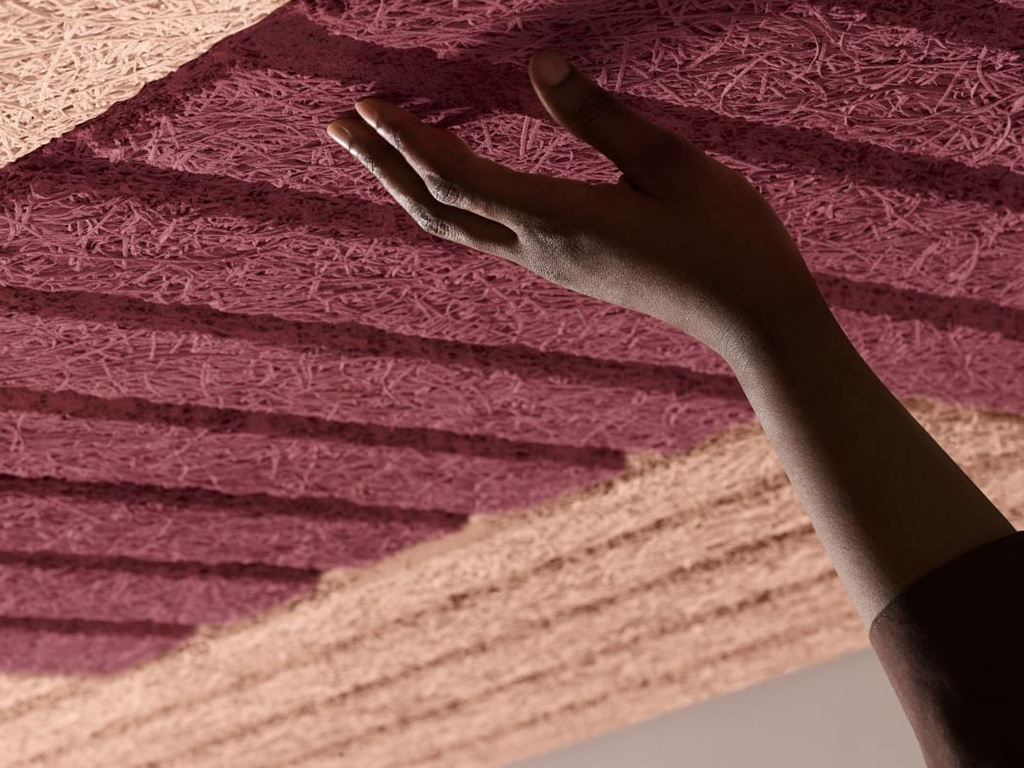

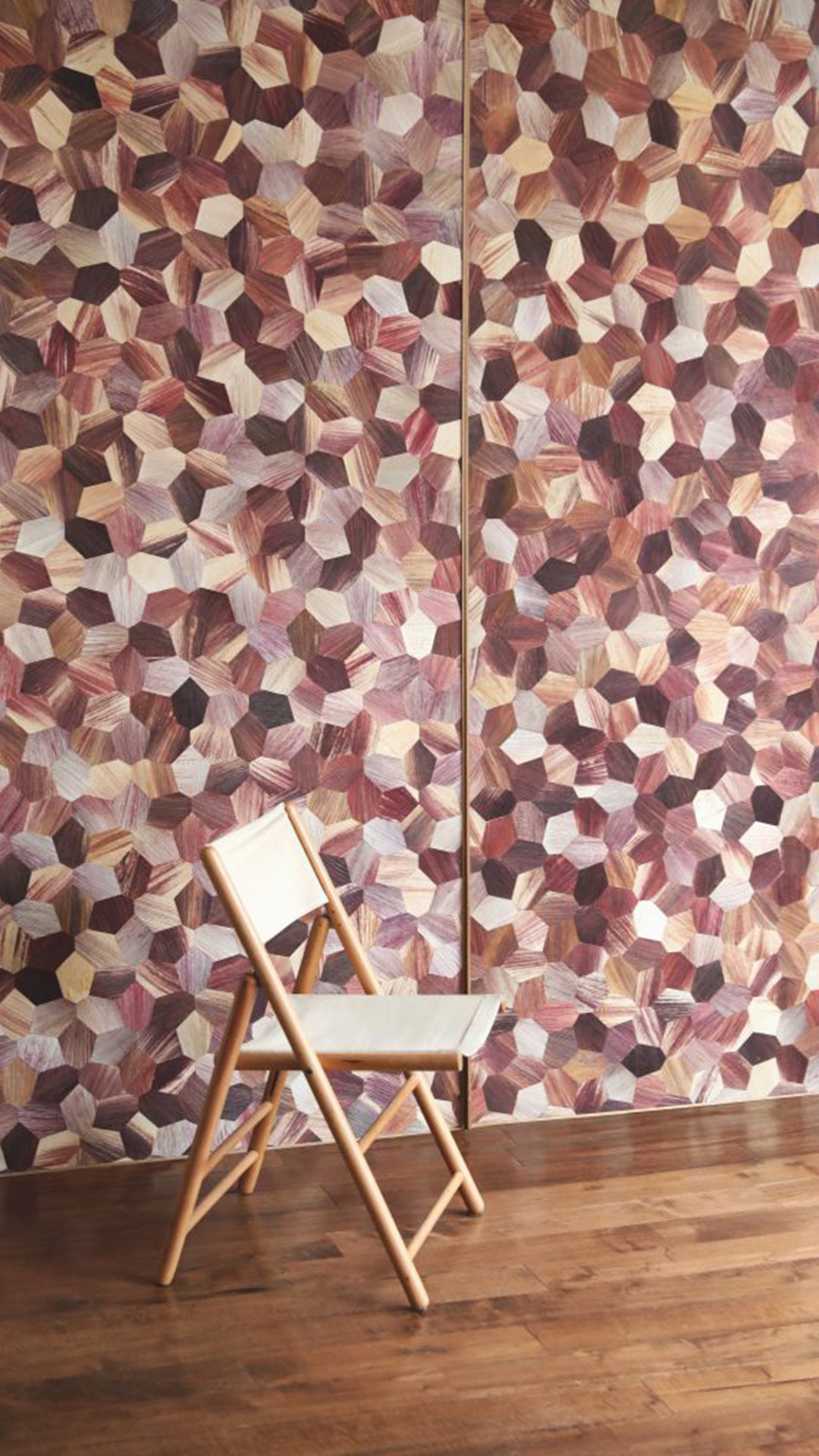

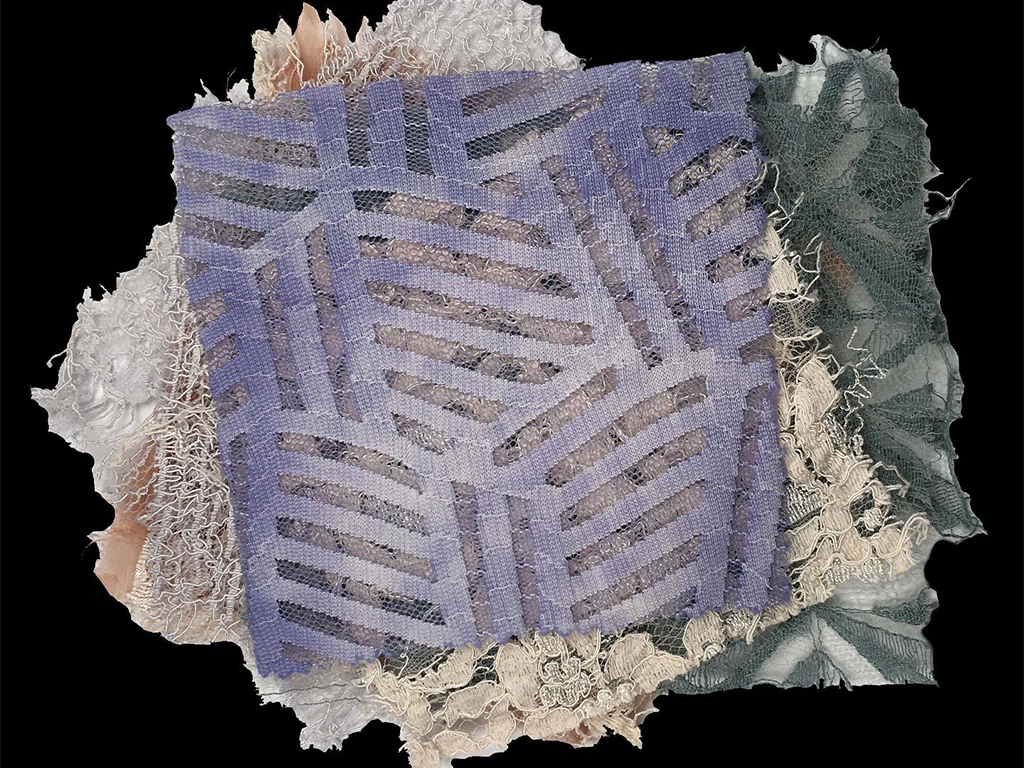

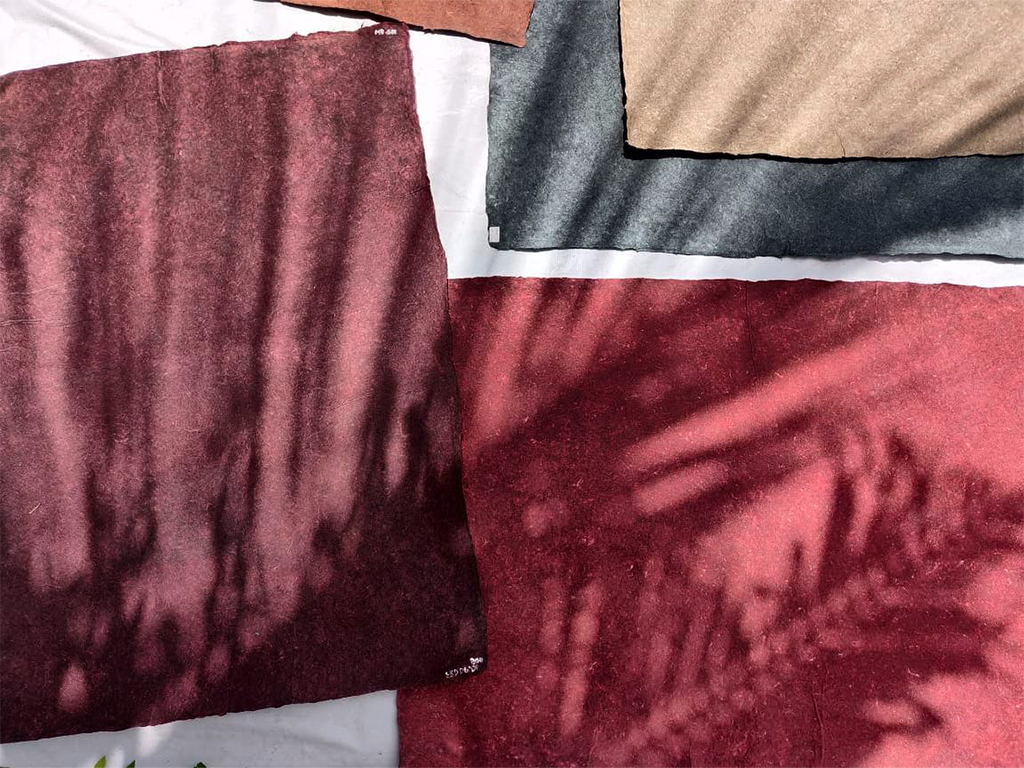

Our revolutionary leather alternative, is crafted with an impressive >85% bio-based ingredients, reflecting our commitment to sustainability.

Our ultimate goal is to evolve Leap® into a fully natural material in the near future. Using the power of apple waste as its foundational element, our material embodies sustainable design principles at its core.

Its innovative three-layered structure is meticulously engineered for easy disassembly at the end of its life cycle, positioning Leap® as a true next-generation material that champions transparency and eco-consciousness.

Country

Denmark

IP

–

PRODUCT DETAIL

| Article Code | – |

| Type | – |

| Finish | – |

MATERIAL COMPOSITIONS

| Properties | Next-gen leather alternative |

| Durability | – |

| Sustainability | – |

TECHNICAL SPECIFICATIONS

| Weight | – kg |

| Density | – kg/cm3 |

| Strength | – mpa |

| Insulation Properties | – |

| Fire Resistance | – |

PERFORMANCE DATA

| Load-Bearing Capacity | – |

| Density | – |

| Fire-Rating | – |

1500 x 25000 (Rolls)

*Leap comes by the linear meter with a usable width of ~1450m.

–

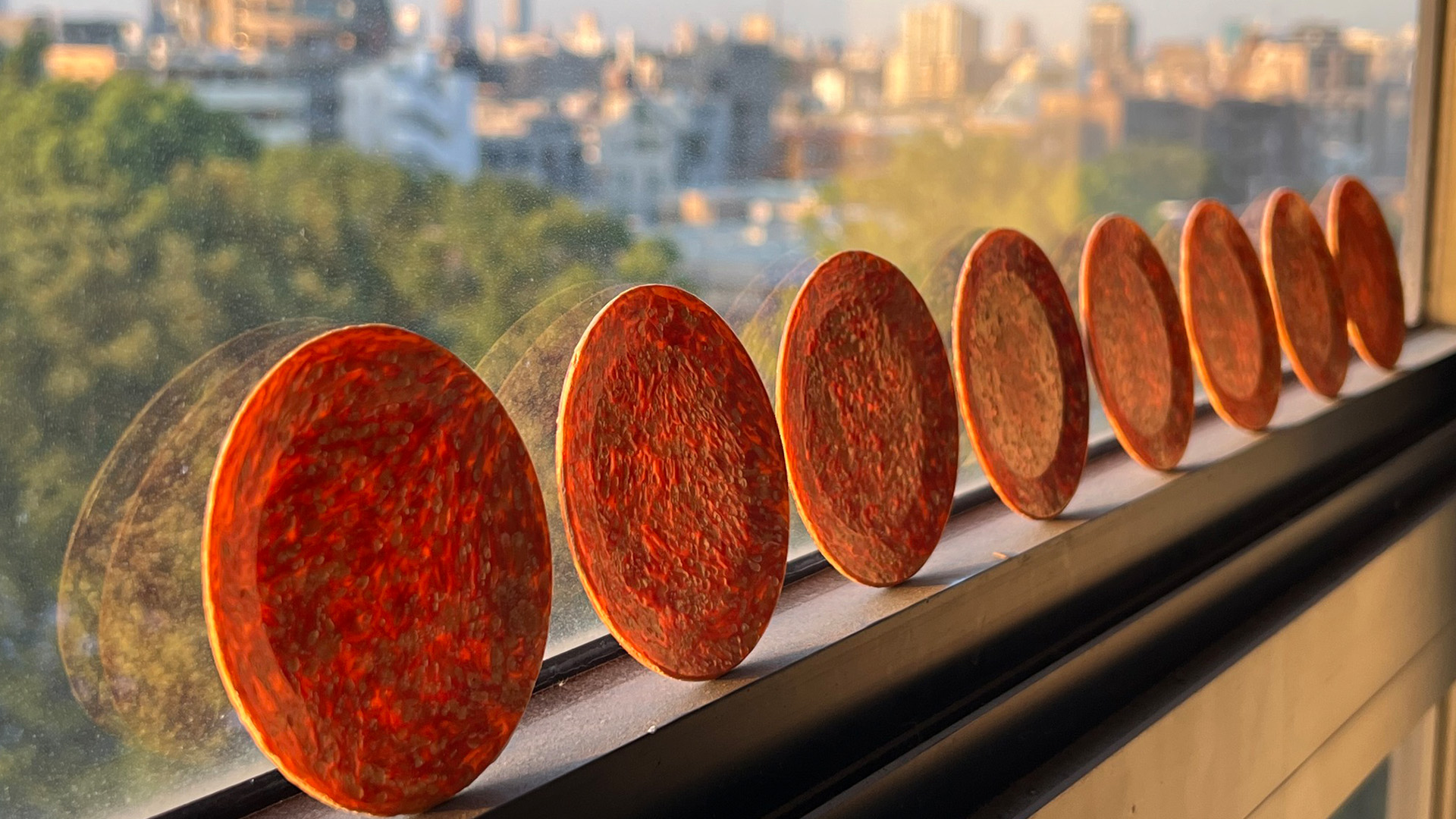

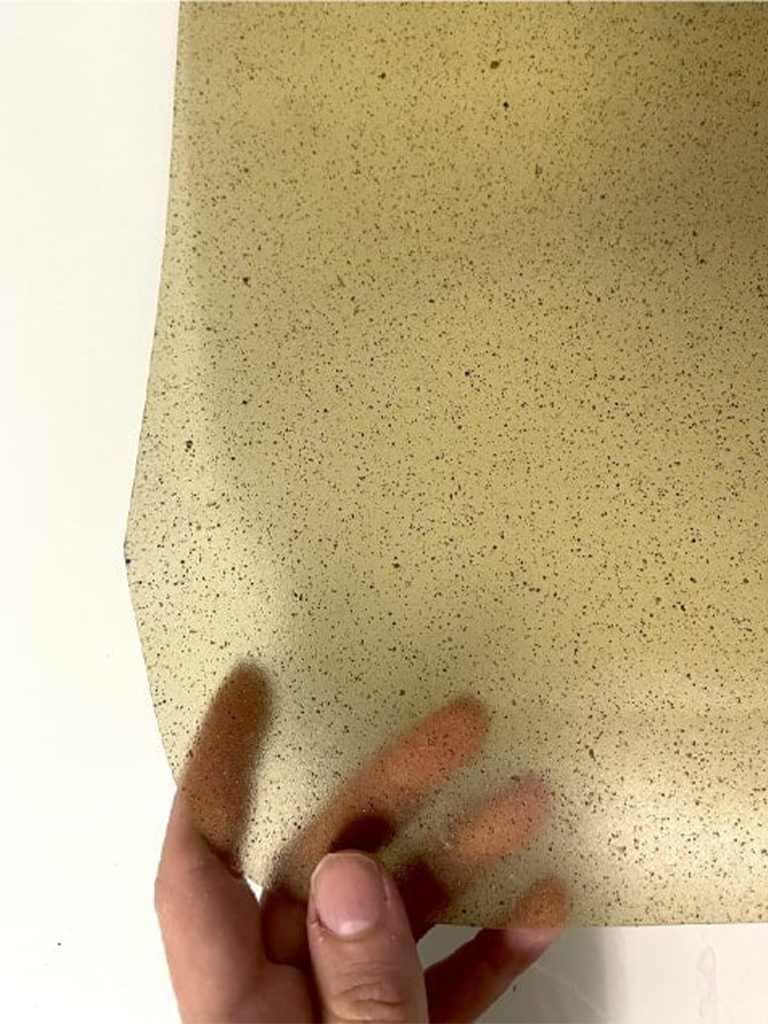

| Process | Using apple waste from European juice and cider producers to create Leap, the leather alternative – next-gen material. The process allows us to use less CO2 and less water usage. |

| Material | Bio-based leather alternative made with apple waste |

| Percentage of Waste | 89% bio-based (this includes apple waste & other natural elements that can be found in Leap) |

| Upcycling Waste | – kg / sqm |

| Green Mark | — |

3D RESOURCES

DIGITAL SAMPLE

SAMPLE & DISTRIBUTION

| Sample Size |

| |

| Distribution Area | – |